Views: 0 Author: Site Editor Publish Time: 2025-09-21 Origin: Site

Have you ever wondered how your medications stay safe and fresh? Blister packing machines play a crucial role in protecting products.

In this article, we will explore what a blister packing machine is and its importance across various industries.

You’ll learn about its functions, history, and how it enhances product safety and compliance.

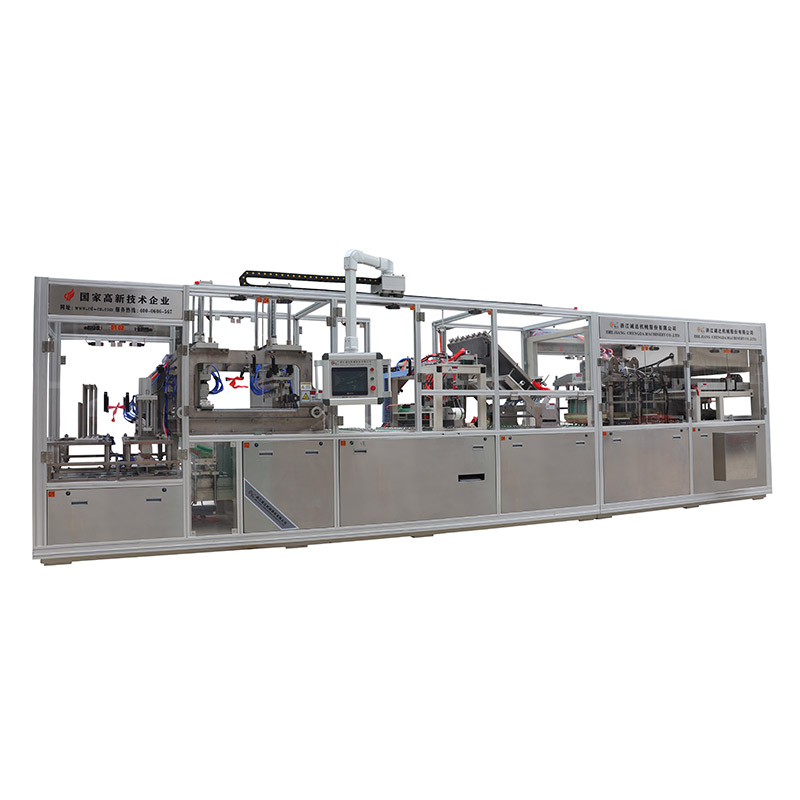

A blister packing machine is a specialized device designed to package products securely. It forms blisters from plastic films, sealing them to protect items inside. This machine is essential for preserving the quality and integrity of various products.

The basic function of a blister packing machine involves several key steps:

1. Thermoforming: Plastic film is heated and shaped into blisters.

2. Filling: Products, like tablets or capsules, are placed into the formed blisters.

3. Sealing: The blisters are sealed with a backing material, often aluminum or paper.

4. Cutting: Finally, the machine cuts the blisters into individual packages.

This process ensures that products remain safe from external factors.

Blister packing technology has evolved significantly over the years. Initially, manual methods were used, which were labor-intensive and less efficient.

● 1960s: The introduction of automated blister packing machines revolutionized the industry.

● 1980s: Advancements in materials and sealing techniques improved product safety.

● Today: Modern machines feature smart technology for real-time monitoring and efficiency.

Blister packing is crucial across multiple sectors. Here’s a quick overview:

● Pharmaceuticals: Ensures medication safety and dosage accuracy.

● Food: Keeps perishable items fresh and extends shelf life.

● Cosmetics: Protects products from contamination and damage.

Each industry benefits from the unique features of blister packing, enhancing both safety and compliance.

Blister packing machines are widely used in:

● Pharmaceuticals: For tablets, capsules, and syringes.

● Food and Beverage: For single-serve portions, snacks, and candies.

● Cosmetics: For creams, gels, and samples.

● Medical Devices: For sterile packaging of surgical instruments and supplies.

These industries rely on blister packing to maintain product integrity and consumer trust.

Blister packing plays a vital role in ensuring product safety. Here’s how:

● Protection from Contamination: Blisters act as a barrier against moisture, light, and air.

● Tamper Evidence: Many blister packs include features that indicate if a product has been tampered with.

● Regulatory Compliance: Blister packing meets stringent industry standards, ensuring safety and traceability.

By utilizing blister packing machines, companies can enhance their product's safety and compliance, ultimately benefiting consumers.

A blister packing machine operates through several core processes. Each step is crucial for ensuring products are securely packaged. Here’s a breakdown:

1. Thermoforming

2. Product Filling

3. Hermetic Sealing

4. Precision Cutting

Let’s dive deeper into each of these processes.

Thermoforming is the first step in blister packing. Here’s how it works:

● Heating: A plastic film is heated until it becomes pliable.

● Molding: The heated film is then shaped into blisters using a mold.

● Cooling: Once formed, the blisters cool and harden, maintaining their shape.

This process creates the protective cavities needed for products.

After forming the blisters, the next step is filling them. This involves:

● Automated Systems: Many machines have automated systems for inserting products.

● Manual Insertion: For smaller operations, workers may fill blisters by hand.

This step ensures that each blister contains the correct product, whether it’s a tablet or a syringe.

Sealing is essential for maintaining product integrity. Here are common sealing methods:

● Heat Sealing: Uses heat to bond the blister to a backing material, like aluminum.

● Cold Sealing: Employs adhesive without heat, suitable for heat-sensitive products.

These methods provide a barrier against moisture, light, and contamination.

Once sealed, the packaging process requires precision cutting:

● Cutting Mechanisms: Machines use blades or lasers to cut blisters into individual packages.

● Quality Control: This step ensures that each package is uniform and meets quality standards.

Precision cutting is vital for efficient packaging and presentation.

Blister packing machines come in various types to suit different needs. Here’s an overview:

● Manual Machines: Ideal for small operations. They require more labor but are cost-effective.

● Automated Machines: Designed for high-volume production. They increase efficiency and reduce labor costs.

● High-Speed Models: These machines can produce large quantities quickly, perfect for large manufacturers.

● Compact Models: Space-saving designs suitable for smaller facilities or specific applications.

Some products require special packaging, such as:

● Syringes: Deep-cavity designs accommodate the length and shape of syringes.

● Creams: Specialized blisters help protect sensitive cosmetic products.

These designs ensure that products are packaged securely and effectively.

Using a blister packing machine offers significant advantages in product protection. Here’s how:

● Barrier Against Contamination

○ Blister packs provide a robust barrier against various contaminants, including:Moisture: Keeps products dry and effective.

○ Light: Protects light-sensitive items.

○ Microbes: Prevents microbial contamination.

This protection is vital for maintaining product integrity, especially in pharmaceuticals and food.

● Tamper Resistance and Compliance with Regulations

○ Blister packaging enhances security by offering tamper-evident features. This is crucial for:Regulatory Compliance: Meets strict guidelines from agencies like the FDA and EU GMP.

○ Consumer Trust: Ensures customers feel safe using the product.

Blister packing plays a critical role in pharmaceuticals:

● Dose-Specific Packaging: Each blister can hold a specific dose, making it easier for patients to understand their medication regimen.

● Boosting Medication Adherence: Simplified administration encourages patients to take their medications as prescribed. For example:

○ Easier Identification: Patients can quickly identify their doses.

○ Convenient Portability: Blister packs are easy to carry, promoting adherence.

Blister packing machines contribute to operational efficiency in several ways:

● Automation and Reduction of Manual Labor

Automated blister packing reduces the need for manual labor, which can:

○ Lower Labor Costs: Fewer workers are needed for packing.

○ Increase Speed: Automation enhances production speed, allowing for higher output.

● Versatility in Handling Different Materials

These machines can handle various materials, including:

○ PVC: Common for many applications.

○ Aluminum: Offers excellent barrier properties.

○ Biodegradable Films: Supports eco-friendly initiatives.

This versatility makes blister packing suitable for diverse industries.

● Scalability for Different Production Needs

Blister packing machines can be tailored for various production scales:

○ Small Labs: Compact models are ideal for limited space.

○ Large Manufacturers: High-speed machines cater to extensive production requirements.

Blister packing machines help companies meet industry standards and enhance branding:

● Meeting Industry Standards

Compliance with regulations is critical. Features like:

○ Lot/Serial Number Printing: Ensures traceability and accountability.

○ Quality Control: Automated checks help maintain high standards.

● Shelf Appeal and Customer Attraction

Blister packs can be visually appealing. Here’s how:

○ Transparent Packaging: Allows consumers to see the product, which can attract attention on shelves.

○ Branding Opportunities: Custom designs can enhance brand recognition.

These benefits make blister packing machines essential for companies aiming to ensure safety, efficiency, and compliance.

Blister packing machines are versatile tools used across various industries. Let's explore their key applications.

In the pharmaceutical sector, blister packing is vital for ensuring product safety and efficacy. Here are some common products packaged:

● Tablets: Blister packs protect tablets from moisture and contamination.

● Capsules: They maintain the integrity of capsules, ensuring they remain effective.

● Inhalers: Blister packing helps keep inhalers sterile and easy to use.

● Pre-Filled Syringes: These require secure packaging to prevent contamination.

This method enhances patient safety and medication adherence.

Blister packing has also found a place in the food and beverage industry. Here are some examples:

● Single-Serve Condiments: Ketchup, mustard, and sauces are often packaged in blister packs for convenience.

● Gummies: Candy manufacturers use blister packs to keep gummies fresh and appealing.

● Portion-Controlled Snacks: Items like nuts or trail mix are packaged in small portions, making them easy for on-the-go consumption.

This packaging keeps food fresh and allows for easy distribution.

In the cosmetics industry, blister packing is used for various products, including:

● Cream Samples: Blister packs allow customers to try products before purchasing.

● Lipsticks: Secure packaging protects lipsticks from damage and contamination.

● Skincare Pods: These single-use pods ensure the product remains uncontaminated until use.

Cosmetic companies benefit from attractive and functional packaging.

The medical device sector relies heavily on blister packing for sterile packaging. Here’s why it matters:

● Syringes: Sterile packaging prevents contamination during use.

● Bandages: Blister packs keep bandages clean and ready for application.

● Diagnostic Kits: These kits require secure, sterile packaging to ensure accurate results.

In this field, maintaining sterility is crucial for patient safety.

Industry | Products Packaged |

Pharmaceuticals | Tablets, capsules, inhalers, pre-filled syringes |

Food and Beverage | Single-serve condiments, gummies, snacks |

Cosmetics | Cream samples, lipsticks, skincare pods |

Medical Devices | Syringes, bandages, diagnostic kits |

Blister packing machines play a significant role in these industries, enhancing safety, convenience, and product integrity.

Selecting the right blister packing machine is crucial for your production line. Here are some key factors to consider.

1. Type of Product and Material Compatibility

a. Different products require specific packaging materials. Consider these points:Pharmaceuticals: Often need materials like PVC or aluminum for optimal protection.

b. Food Items: May require barrier films to maintain freshness.

c. Cosmetics: Compatibility with materials that enhance shelf appeal is essential.

2. Production Volume and Scalability Needs

a. Assess your production requirements:Low Volume: If you’re a small lab, a compact machine may suffice.

b. High Volume: Large manufacturers need high-speed machines for efficiency.

c. Scalability: Choose a machine that can grow with your business needs.

3. Compliance with Regulatory Standards

a. Regulatory compliance is non-negotiable, especially in pharmaceuticals and food:FDA Regulations: Ensure the machine meets all necessary standards.

b. Quality Control: Look for features that support traceability, like lot number printing.

4. Cost vs. Value Analysis

a. Understanding the financial aspects is vital:Initial Investment: Evaluate the upfront costs of the machine.

b. Long-Term Benefits: Consider how it will save money over time through efficiency and waste reduction.

Calculating ROI helps justify your investment. Here’s how to analyze it:

● Reduced Waste: Efficient machines minimize material waste, saving costs.

● Enhanced Product Appeal: Attractive packaging can boost sales, leading to increased revenue.

● Long-Term Savings: Consider lower labor costs and higher production speeds as ongoing benefits.

Factor | Considerations |

Product Type | Material compatibility with product needs |

Production Volume | Low vs. high volume requirements |

Regulatory Compliance | Meeting industry standards |

Cost vs. Value | Initial costs vs. long-term savings |

ROI | Reduced waste and improved sales potential |

Choosing the right blister packing machine requires careful consideration of these factors. By analyzing your specific needs, you can make an informed decision that benefits your business in the long run.

Blister packing machines are essential for various industries. They ensure product safety and extend shelf life.

Key points discussed include their applications in pharmaceuticals, food, cosmetics, and medical devices.

Looking ahead, advancements in blister packing technology promise greater efficiency and innovation.

Sustainability is becoming increasingly important, driving the need for eco-friendly packaging solutions.

A: The main components include the forming station, sealing station, feeder, and cutting mechanism.

A: Regular cleaning, lubrication, and inspection of parts are essential for optimal performance.

A: Pharmaceuticals, food and beverage, cosmetics, and medical devices benefit significantly.

A: Yes, they can accommodate various products, including tablets, capsules, and single-serve snacks.

A: Blister packing materials can contribute to waste, but advancements are focusing on eco-friendly alternatives.