Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

In the dynamic world of manufacturing and packaging, the role of blister packaging machines has become increasingly significant. These machines are designed to provide efficient, reliable, and high-quality packaging solutions across various industries. Zhejiang Chengda Machinery Co., Ltd., a leading manufacturer of automatic blister packaging machines, has been at the forefront of innovation, offering state-of-the-art solutions that meet the evolving needs of businesses worldwide.

This article delves into the diverse applications of blister packaging machines, highlighting their importance in industries such as pharmaceuticals, food, cosmetics, electronics, and more. We will explore how these machines enhance product protection, consumer safety, and operational efficiency, while also discussing the latest trends and advancements in blister packaging technology.

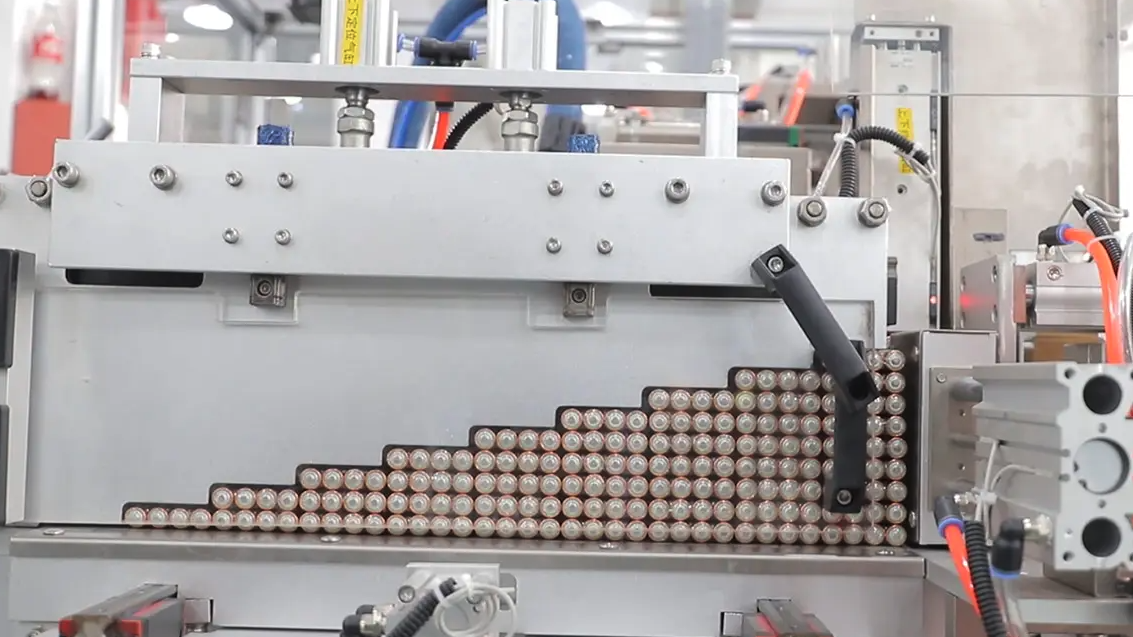

A blister packaging machine is a device that forms small cavities—called blisters—into a plastic or aluminum sheet. It fills those cavities with tablets, capsules, foods, or even electronics. Then it seals them using foil or film. The result is a compact package that is tamper-resistant, easy to store, and ready for display. People see blister packs every day in pharmacies, toy stores, and supermarkets.

Unlike bottle fillers or pouch sealers, a blister packaging machine creates individual doses or units. Bottling lines pack many pieces together in one container. Pouch sealers close flexible bags filled with bulk product. In contrast, blister machines give each tablet or small item its own compartment. This reduces contamination, improves dosing accuracy, and enhances consumer safety.

When it comes to packaging, there are several key differences that can significantly impact its functionality and application. Unit packaging focuses on individual items, providing separate packaging for each product. This is ideal for retail settings where customers may purchase single units. In contrast, bulk packaging is designed for large quantities of products, often used in wholesale or industrial contexts to reduce packaging costs and improve efficiency.Another important distinction lies in the design of the packaging itself. Sealed cavities offer a high level of protection, preventing contamination and preserving the integrity of the contents. This is particularly crucial for perishable goods or sensitive products. On the other hand, open containers are more accessible and convenient for certain uses, such as when products need to be easily dispensed or when visibility of the contents is a priority.

Tamper resistance is a critical feature for ensuring product safety and security. Packaging that is tamper-resistant is designed to prevent unauthorized access and tampering, which is essential for products like pharmaceuticals or high-value items. In contrast, simple closure mechanisms, while still providing some level of protection, are more basic and may not offer the same degree of security. Lastly, better visibility for retail display is a key consideration in packaging design. Transparent or windowed packaging allows customers to see the product clearly, which can enhance appeal and drive sales. This is particularly important in competitive retail environments where products need to stand out on the shelves.

Blister packaging is indispensable in the pharmaceutical sector, where product integrity and consumer safety are paramount. Blister packs protect medications from moisture, light, and contamination, ensuring they remain effective and safe for consumption.

Tablets and Capsules: Immediate-release and coated tablets (e.g., IBU, Metformin, Amlodipine) can be packaged at speeds of 300–400 blisters per minute. Controlled-release cores benefit from pre-heat forming to avoid shell cracking.

Enteric-Coated Pellets: These are blistered under nitrogen flush (<1% residual O₂) to maintain stability for proton-pump inhibitors.

Orally Disintegrating Tablets (ODTs): High friability ODTs are handled with soft-form tooling to reduce punch impact by 30%.

Oncology Tablets: Tablets containing <10 µg API per dose are processed in isolators with glove-port access, ensuring validated cleaning to <1 µg/swab.

Hormone Replacement Patches: Alu-Alu cold-form foil with 100% pin-hole camera inspection guarantees zero light transmission.

Lyophilized Rabies Vaccine Vials: Nested in 10-cavity thermoformed trays sealed with peelable Tyvek®, validated down to -45°C freeze-drying.

mRNA Pre-Filled Syringes: Single-dose syringes are blistered in PETG forming web with desiccant cavities, maintaining <0.5% residual moisture after 24 months at 25°C/60% RH.

In the food sector, blister packaging enhances product freshness, extends shelf life, and provides tamper-evident solutions. This makes it ideal for a wide range of food products, from candies and chocolates to snacks and beverages.

Candies and Chocolates: Blister packs provide an airtight seal, protecting products from moisture and oxidation.

Snacks: Products like chips and nuts can be packaged in multi-cavity blisters, ensuring freshness and reducing packaging waste.

Blister packaging is widely used in the electronics industry to protect small components from damage, moisture, and tampering. This ensures that products remain functional and safe for consumers.

Batteries: CR2032 coin cells are packed in conductive PS trays to prevent short-circuiting, with surface resistivity <10⁴ Ω/sq.

USB Drives: Blister packs provide a secure and tamper-evident solution, ensuring product integrity.

Blister packaging enhances product visibility and provides tamper-evident solutions, making it ideal for personal care and cosmetic products. This ensures that consumers receive safe and high-quality products.

Razors and Toothbrushes: Blister packs provide a secure and tamper-evident solution, ensuring product integrity.

Skincare Products: Products like serum capsules are packaged in transparent Aclar® forming web, with tamper-evident laser scoring.

Blister packaging is also used in the veterinary and pet care industries to protect medications and supplements from moisture and contamination. This ensures that products remain safe and effective for animals.

Deworming Chews: Heart-shaped deworming chews for dogs are packaged in food-grade color masterbatch in PVC forming web, with mold cavities engraved with logos for brand identity.

Aquaculture Micro-Pellets: These are filled via multi-head weigher into 20-cavity blisters, with desiccant canisters inserted for tropical transport.

Blister packaging is ideal for nutraceuticals and probiotics, ensuring that products remain stable and effective. This makes it a popular choice for vitamins, supplements, and probiotic tablets.

Gummy Multivitamins: These are handled by soft-drop conveyors to avoid deformation, with forming temperatures kept at 55°C to prevent vitamin degradation.

Probiotic Tablets: Freeze-dried probiotic tablets (50 B CFU) are blistered under <5% RH environment with inline moisture analyzers, extending shelf life from 18 to 36 months.

Blister packaging is also used in cold-chain logistics to ensure that temperature-sensitive products remain stable during transport and storage. This is crucial for vaccines, biologics, and other perishable items.

Temperature Loggers: Co-packed with vaccine blisters, RFID tags are welded into cavity walls for seamless track-and-trace during -20°C transport.

Dry-Ice Shipment Kits: These include molded EPS inserts with blister cavities for vials and phase-change material (PCM) bricks, validated for 120 hours below -60°C.

| Industry | Application Type | Description |

|---|---|---|

| Pharmaceutical Industry | Solid Dosage Forms | Tablets and capsules packaged at high speeds; enteric-coated pellets under nitrogen flush; ODTs handled with soft-form tooling. |

| High-Potency and Hormonal Products | Oncology tablets in isolators; hormone patches with Alu-Alu foil and pin-hole inspection. | |

| Vaccines and Biologics | Lyophilized vaccine vials in thermoformed trays; mRNA syringes with desiccant cavities. | |

| Food Industry | Confectionery and Snacks | Candies, chocolates, and snacks in multi-cavity blisters for freshness and reduced waste. |

| Electronics and Hardware | Small Electronics | Batteries in conductive PS trays; USB drives in tamper-evident blister packs. |

| Personal Care and Cosmetics | Cosmetics | Razors, toothbrushes, and skincare products in transparent Aclar® forming web with tamper-evident features. |

| Veterinary and Pet Care | Animal Medications | Heart-shaped deworming chews for dogs in food-grade PVC; aquaculture micro-pellets in 20-cavity blisters with desiccant canisters. |

| Nutraceuticals and Probiotics | Vitamins and Supplements | Gummy multivitamins handled by soft-drop conveyors; freeze-dried probiotic tablets under low RH environment. |

| Cold-Chain and Data Logging | Temperature-Sensitive Products | Temperature loggers co-packed with vaccine blisters; dry-ice shipment kits with EPS inserts and PCM bricks for cold validation. |

Advances in automation and robotics are making blister packaging machines more efficient and precise. Automated feeding systems, vision inspection protocols, and robotic handling ensure consistent product quality and reduce human error.

The push for sustainable packaging solutions is leading to the development of more environmentally friendly materials. Biodegradable and recyclable films are becoming increasingly popular, reducing the environmental impact of blister packaging.

The integration of smart technologies, such as RFID tags and data loggers, is enhancing the traceability and monitoring of blister packs. This ensures that products remain stable and safe during transport and storage.

A blister packaging machine is a device that forms small cavities—called blisters—into a plastic or aluminum sheet. It fills those cavities with tablets, capsules, foods, or even electronics. Then it seals them using foil or film. The result is a compact package that is tamper-resistant, easy to store, and ready for display.

Blister packaging is particularly beneficial for the following industries:

Pharmaceuticals: Ensures product safety and compliance with regulations.

Food: Extends shelf life and provides tamper-evident solutions.

Cosmetics: Enhances product visibility and provides tamper-evident solutions.

Electronics: Protects small components from damage and tampering.

Veterinary and Pet Care: Ensures medications and supplements remain safe and effective.

Regular maintenance is crucial to ensure the longevity and efficiency of a blister packaging machine. Key maintenance tasks include regularly cleaning the machine to prevent contamination, ensuring all moving parts are properly lubricated, and regularly checking and calibrating the machine to ensure precision. Inspecting tooling for wear and replacing it as needed is also important, along with keeping the machine’s software up to date for optimal performance.

Blister packaging machines enhance operational efficiency through high-speed production, enabling the quick creation of large volumes. They also reduce labor costs by minimizing the need for manual labor through automated processes. Additionally, these machines optimize material usage, which helps in reducing waste. Advanced features like vision inspection ensure zero-defect production, further enhancing overall quality control.

Blister packaging machines play a crucial role in various industries, providing efficient, reliable, and high-quality packaging solutions. They enhance product protection, consumer safety, and operational efficiency, making them indispensable in the modern manufacturing landscape. As technology continues to advance, blister packaging machines will become even more sophisticated, offering greater automation, sustainability, and smart capabilities.

Investing in the right blister packaging machine ensures that businesses can meet their production goals while maintaining product integrity and consumer trust. Zhejiang Chengda Machinery Co., Ltd. offers state-of-the-art solutions that meet the evolving needs of businesses worldwide, making them a trusted partner in the packaging industry.

Whether you are in the pharmaceutical, food, cosmetics, electronics, or any other industry, a blister packaging machine can provide the protection, convenience, and compliance you need to succeed.