Views: 0 Author: Site Editor Publish Time: 2025-07-24 Origin: Site

A blister packaging machine makes, fills, and seals products in plastic or aluminum spaces. These spaces are called blisters. The packs are safe and you can see what is inside. Companies use these machines to pack things like medicine tablets, capsules, medical tools, and even things like batteries and makeup. The pharmaceutical industry uses these machines the most. They need them for single dose medicines. Food and other goods companies also use blister packaging. It helps keep things clean and safe.

The global blister packaging machine market was worth $42.2 billion in 2023. This growth is because of high needs in medicine and more use in other industries.

Blister packaging machines make safe packs. These packs are clear and protect things like medicine and small items. They keep products safe from damage and dirt.

There are four main types of blister machines. These are manual, semi-automatic, fully automatic, and tabletop. Each type works best for different jobs and speeds.

The machine heats plastic sheets. It forms pockets in the plastic. Then it fills the pockets with products. Next, it seals them with a backing. Last, it cuts the packs to the right size.

Materials like PVC, aluminum foil, and eco-friendly films are used. These materials keep products fresh and safe. They also help lower harm to the environment.

When you buy a blister packaging machine, think about the type you need. Also look at speed, support, and eco-friendly features. Pick what matches your business needs.

Blister packaging machines come in different types. Each type is good for certain jobs and industries. The main types are manual, semi-automatic, fully automatic, and tabletop machines.

Manual blister packaging machines are best for small jobs. People do every step by hand, like putting in products and sealing packs. These machines are used in labs, pharmacies, and research places. They can make up to 20 blisters each minute. Manual machines are cheaper and easy to learn. They work well for testing new medicines or for clinical trials.

Semi-automatic blister packaging machines mix hand work and machine work. People put in the products, but the machine seals and cuts the packs. These machines are good for small or medium batches. They save money and are flexible. For example, the BlisterMate machine can make, seal, and cut packs for tests or small jobs. Semi-automatic machines can change quickly for different products.

A fully automatic blister packaging machine does all the work by itself. It makes, fills, seals, and cuts blisters with no help. These machines are fast and make packs that look the same. They are used for big jobs in medicine and other goods. Some machines can make up to 600 blisters each minute. They can also work with other machines like cartoners and tube fillers. These features help companies pack things faster and better.

Tip: Fully automatic blister packaging machines need more care, but they save on workers and make more packs.

Tabletop blister packaging machines are small and easy to move. They are good for labs, hospitals, and small companies. These machines do not make many packs at once and need people to help. Tabletop machines like the EZ Blister are easy to set up and can make different pack shapes. They are good for small jobs and can be moved to different places.

| Machine Type | Output Capacity / Use Case | Efficiency and Automation Level |

|---|---|---|

| Manual / Tabletop | Up to 20 blisters per minute; labs, R&D | People do most work; not very fast |

| Semi-Automatic | Small to medium batches | Some machine help; saves money and is flexible |

| Fully Automatic | High-volume production | No help needed; fastest and best quality |

Blister packaging machines can work with other machines. Some examples are cartoners, tube feeders, and vision tools. These help companies pack products in a complete way. Some lines use a roller blister packaging machine to make packs even faster.

A blister packaging machine uses heat and pressure to make packs. It starts by pulling a plastic sheet into the machine. The machine heats the plastic until it gets soft. Then, it shapes the plastic into small pockets called blisters. These blisters hold things like tablets or small devices. After making the blisters, the machine puts the product inside each one. Next, it covers the blisters with a backing, like aluminum foil or paper. Heat and pressure seal the pack so it stays closed. At the end, the machine cuts the packs to the right size and shape.

Note: The main job of a blister packaging machine is to keep products clean, safe, and easy to use.

A blister packaging machine works in many steps. Each step helps protect the product and keep it high quality.

Material Preparation and Loading: Workers put plastic sheets and backing, like aluminum foil, into the machine. They also get the product feeding system ready.

Plastic Sheet Preheating: The machine heats the plastic sheet to make it soft for shaping.

Forming the Blisters: The machine shapes the soft plastic into pockets using molds. It can use vacuum or pressure to make different shapes.

Filling the Cavities: The machine puts the product into each blister pocket. This can be done by hand or by machine.

Sealing: The machine covers the filled blisters with a backing. It uses heat and pressure to seal the pack tight.

Cooling: The sealed packs cool down fast to keep their shape.

Coding and Labeling: The machine prints numbers, dates, or other info on the pack.

Cutting and Perforating: The machine cuts the strip into single or grouped blister packs.

Quality Check: The machine checks each pack for weight, seal, and looks. Bad packs are taken out.

Collection and Packaging: The finished packs are collected for more packing or shipping.

These steps help make sure every pack is safe and good quality. In medicine and food, blister packaging must follow strict rules. These rules include using safe glue, ink, and rubber. Packs must show if they have been opened and keep products safe from water and dirt.

Blister packaging machines have many features to help with speed, safety, and quality. New machines use touch screens, sensors, and smart systems. These help workers set up and watch the process.

Temperature, Pressure, and Time Controls: Workers can change these to get the best seal. The right settings stop leaks and keep products safe.

Automatic Feeding and Inspection: Many machines use feeders and cameras to place products and check for mistakes.

Coding and Printing Systems: Machines can print numbers, dates, and barcodes for tracking.

Safety Features: Emergency stops, guards, and alarms keep workers and products safe.

There are two main types of blister packaging machines: rotary and flat-plate. Rotary machines use a spinning part to move blisters through each step. This lets them work fast and make many packs. Rotary machines are best for big jobs and can make up to 1,200 packs each minute. Flat-plate machines use a flat area for shaping and sealing. They are easier to use and fix. They can make different shapes but are slower.

| Machine Type | Typical Speed Range (CPM) | Notes on Efficiency and Technology |

|---|---|---|

| Thermoforming Machines | 10 to 60 | Speed depends on mold and plastic type |

| Cold Forming Machines | Up to 120 | Best for strong barrier packaging |

| High-Speed Rotary | Up to 300 (some up to 1,200) | Best for large-scale, fast production |

| In-line Machines | 20 to 100 | Used in integrated production lines |

Modern blister packaging machines use smart motors, feeders, and cameras. These help balance speed and quality. Workers can change settings fast for different products. This makes the machines good for many jobs.

Tip: Training and care help workers stop problems like sealing issues or jams. Good care keeps the blister packaging machine working well and makes sure packs are high quality.

Blister packaging uses different plastics and films. Each one helps keep products safe. Here are some common plastics:

PVC (Polyvinyl Chloride): This plastic is clear and easy to shape. It is strong and keeps out water.

PVDC-coated films: These films give more protection from water and air. They are often used with PVC to make a stronger barrier.

PCTFE (Aclar film): This film gives the best shield from water and gases. It is used for medicines that need extra care.

Polypropylene (PP): This plastic can be recycled and is better for the earth. It is harder to shape but works for some packs.

Cyclic Olefin Copolymers (COC): These plastics do not have chlorine and block water well. They are good for deep blister spaces.

| Material / Film Type | Usage in Blister Packaging | Key Properties and Characteristics |

|---|---|---|

| PVC | Forming film | Clear, easy to shape, strong, widely used in pharmaceutical blister packaging. |

| PVDC-coated films | Coating for forming film | High barrier to moisture and oxygen, flexible, heat-sealable. |

| PCTFE (Aclar) | Forming film laminate | Best moisture and gas barrier, transparent, stable. |

| Polypropylene (PP) | Forming film alternative | Recyclable, good barrier, some shaping challenges. |

| COC | Forming film enhancer | Moisture barrier, chlorine-free, customizable. |

Backing materials close the blister and keep products safe. The type of backing changes how long things stay fresh. Some common backings are:

Aluminum foil: This stops light, air, and water from getting in. It is used for medicines that need strong protection.

Paper laminates: These mix paper with other things for easy opening and safety.

PET and PETG: These plastics make packs stronger and easier to open.

PLA: This is a green choice that breaks down and makes less trash.

The right backing keeps the blister closed tight. It also helps the product last longer and stay safe.

Note: Some backings, like PVDC and Aclar, give more safety for sensitive things. Aluminum foil can be recycled, but it is hard if mixed with plastic.

Eco-friendly blister packaging is getting more popular. Companies use new materials to help the planet. Some choices are:

Mono-material PP blisters: These packs use only polypropylene, so they are easy to recycle. They protect products and use less energy to make.

All-paper blisters: These packs use only paper and can go with paper recycling. Some brands use these for their goods.

Biodegradable and compostable films: Materials like PLA break down on their own and help stop plastic waste.

Circular economy designs: Some packs use QR codes or smart ideas to help with recycling and reuse.

Eco-friendly blister packaging can cost more, but it helps cut pollution and supports green goals. These new materials still keep products safe and work with most blister packaging machines.

Blister packaging keeps products safe from water, dirt, and damage. Each blister holds one item or dose, so things stay clean and fresh. This is important for medicine because it helps it last longer. The clear plastic lets people see what is inside before they buy it. This helps people trust the product and know it is complete. Companies can make blisters in special shapes to fit their products. They can also add printed info or QR codes. These custom features help brands stand out and share details with buyers.

Blister packaging shows if someone tried to open it. The clear cover and strong backing, like aluminum foil, show damage right away. If the blister is broken or the seal is ripped, people know it may not be safe. This is very important for medicine, where safety is key. Blister packs can have printed codes, dates, or barcodes to help track each pack. Unlike other packaging, blister packs show tampering for each dose. This gives extra safety.

| Feature | Strip Packaging | Blister Packaging |

|---|---|---|

| Cost | 15-20% cheaper; uses thin foil | 10-15% more expensive; uses thicker films |

| Protection | Good barrier; less crush-resistant | Excellent barrier; rigid and crush-resistant |

| User Convenience | Easy to tear; compact; less clear labeling | Clear dose visibility; better for tracking; harder to open for some |

Blister packaging protects products better than strip packaging. It also shows if someone tried to open it. Blister packs keep things safe longer and let users see each dose. Strip packaging costs less and is easy to carry, but it does not protect as well or show tampering as clearly.

When buying a blister packaging machine, companies should think about a few things:

After-sales support is important. This means training, spare parts, and help when needed.

The maker’s reputation matters. Buyers should check for good quality, certifications, and service.

The machine type, speed, and what materials it works with should fit the company’s needs.

Warranty and clear contracts help protect the company’s money.

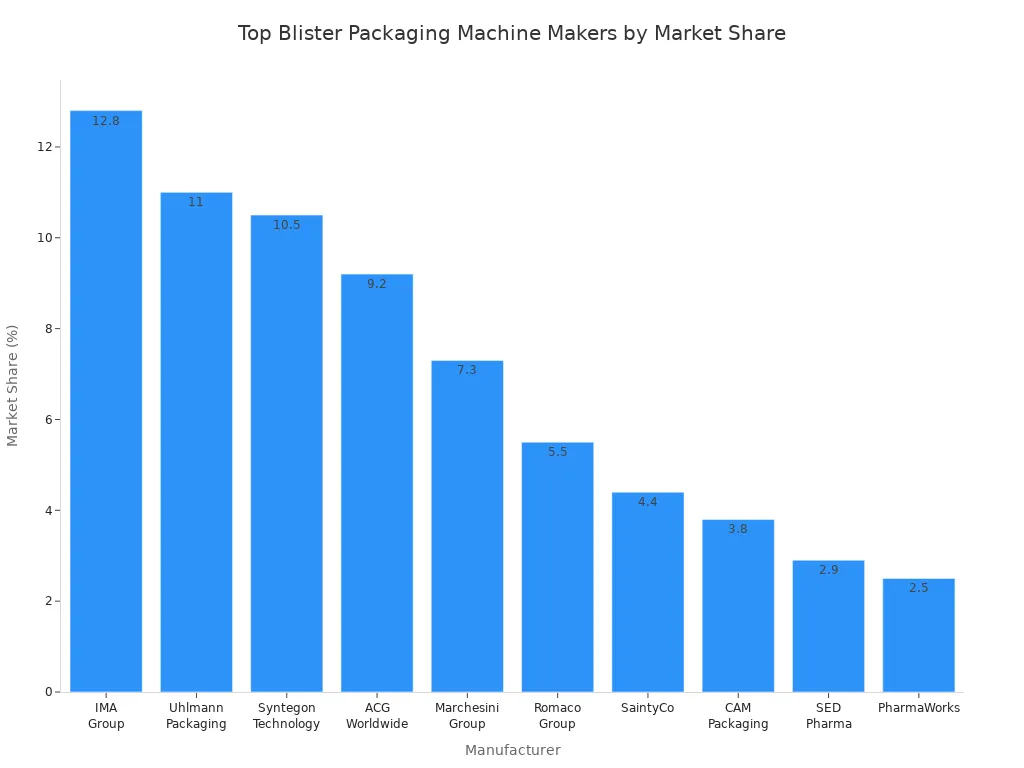

Some top makers are Uhlmann Packaging Group, IMA Group, Syntegon Technology, and ACG Worldwide. These companies have machines with new features, strong support, and good quality.

Blister packaging keeps products safe and shows if someone opened them. There are many kinds of blister machines. Each machine has special features for certain jobs. Companies should think about speed and how well the machine fits their product. They should also check quality control and how much work the machine does by itself.

Being eco-friendly is important. New blister packaging uses green materials and smart tech to follow rules and help the earth.

| Future Trends in Blister Packaging |

|---|

| More machines that work by themselves |

| Better materials for the environment |

| Smart tools to keep products safe |

A blister packaging machine can pack many things. It packs tablets, capsules, medical devices, and batteries. It also packs chewing gum and small goods. Many companies use these machines. They help keep products safe and simple to use.

The speed depends on the machine type. Manual machines make up to 20 packs each minute. Fully automatic machines can make 600 packs or more every minute.

Thermoforming uses heat to shape plastic into blisters. Cold forming shapes aluminum but does not use heat. Thermoforming is faster than cold forming. Cold forming protects sensitive products better.

Yes, many machines can use green materials. They can use plastics that can be recycled. Some use paper films or materials that break down. Companies pick these to make less waste and help the earth.

Blister packs have strong seals and clear covers. If someone opens or breaks the pack, you can see it right away. This helps keep the product safe and protects users.