Views: 0 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

Do you know how to operate a blister machine effectively? Many overlook the crucial steps, leading to inefficiency and poor-quality output. In this post, we'll guide you through the entire process— from preparation to shutdown. Expect practical tips and best practices to ensure smooth operation and top-notch production.

Before operating a blister machine, proper preparation is essential for smooth production and high-quality output. This section outlines the necessary steps to take before starting the machine, ensuring it operates efficiently and effectively.

Before turning on the machine, inspect all components to ensure they are in good condition. Check the molds, heating elements, and sealing platens for any damage, dirt, or misalignment. Any debris or malfunctioning parts can cause defects in the final product. Pay close attention to the alignment of the molds and ensure that they are securely attached to the machine.

The plastic films and backing materials you use should meet the specific requirements of your product. Films like PVC, PET, and PP must be chosen based on their thickness and quality. Materials with inconsistencies, such as tears or wrinkles, can lead to issues during the forming process. Be sure to adjust the material tension to prevent slack or stretching as the machine runs.

Material Type | Thickness Range | Application |

PVC | 0.2–0.4 mm | Standard packaging |

PET | 0.2–0.5 mm | Medical and food packaging |

PP | 0.1–0.3 mm | Low-cost packaging |

Safety should always be a priority. Ensure that all emergency stops, safety guards, and ventilation systems are fully functional. The machine should also be free from any obstructions that could interfere with safe operation. Protective equipment, such as heat-resistant gloves and eye protection, should be worn to prevent injury.

The next step is to calibrate the machine’s tools and molds. This ensures that everything is aligned according to the product specifications. Calibration should be done carefully to avoid any misalignment, as this can lead to uneven blisters and wasted materials. If your machine has quick-change tooling, make sure the molds are securely fastened and aligned properly to avoid issues during production.

By ensuring all equipment is inspected, materials are set up correctly, safety protocols are in place, and tools are calibrated, you can begin the machine operation with confidence, leading to a smoother, more efficient production process.

Setting the correct parameters before starting the blister machine is crucial for ensuring smooth operation and high-quality packaging. Proper adjustments to thermal settings, speed, pressure, and format customization can prevent defects and optimize efficiency throughout the production process.

The first key parameter to adjust is the thermal settings. These include both forming and sealing temperatures, which should be set accurately using closed-loop PID control. This system helps maintain consistent temperatures, preventing the film from melting or forming incompletely. If the temperature is too high, the material may melt, causing material waste or defects. On the other hand, if the temperature is too low, the blister formation may be incomplete, affecting the integrity of the packaging.

Material Type | Forming Temperature (°C) | Sealing Temperature (°C) |

PVC | 80–100 | 140–160 |

PET | 100–120 | 160–180 |

Aluminum Foil | 120–140 | 180–200 |

Next, you need to adjust the production speed and sealing pressure. The speed of the machine depends on the type of material being used and the complexity of the blister design. For instance, rotary machines can achieve speeds of 180–450 cycles per minute, while linear machines may operate at 80–180 cycles per minute.

Sealing pressure is another critical factor. Different materials require different levels of pressure for optimal sealing. Aluminum foil typically requires higher sealing pressure compared to materials like PVC. Setting the appropriate speed and pressure ensures that the blister packs are formed and sealed properly, without overloading the system or compromising the packaging quality.

The machine's format must be customized to match the product specifications. This includes inputting product dimensions and the number of cavities in the blister mold. Ensuring the correct format setup is essential for producing accurately sized blisters that fit the product. Additionally, setting the cutting parameters ensures that the final blister pack meets the required size and shape. This customization step allows you to handle various products without needing extensive reconfiguration.

During production, it's essential to monitor all machine parameters in real-time. Many blister machines have built-in software to log settings such as temperature, pressure, and production speed. This data is important for traceability, especially in industries like pharmaceuticals. Compliance with regulations such as 21 CFR Part 11 requires that all settings are recorded for audit purposes. By logging production data, you can track any deviations, ensuring that all batches meet the required standards and reducing the risk of defects.

Tip: By properly setting the thermal, speed, and pressure parameters, and ensuring that all format specifications are customized for the product, you ensure optimal machine performance. Additionally, continuous monitoring and logging keep the process efficient and compliant with industry standards.

Operating a blister machine involves several crucial steps that need to be followed to ensure smooth and efficient production. From loading materials to the final cutting process, each phase plays a significant role in producing high-quality blister packs. Let’s take a closer look at each step.

The first step in the operation is loading the plastic film and backing materials onto the respective rolls. The plastic film, typically made of PVC, PET, or PP, needs to be placed securely on the unwind station. Ensure the film is properly threaded through the pre-heating system and into the forming station. It’s essential to maintain correct tension throughout the process to avoid material stretching or slack, which can affect the quality of the final product. For the backing materials, such as aluminum foil or cardboard, ensure they are properly aligned with the sealing station.

Before the plastic film is formed into cavities, it needs to be pre-heated. This step is crucial for optimizing the material’s ability to stretch without tearing. The film is softened through a heating process, with the required temperature varying based on the material type. For instance, PVC typically requires a pre-heating temperature between 80–100°C. Pre-heating not only helps in achieving proper molding but also reduces material waste by improving the efficiency of the forming process.

Material Type | Pre-Heating Temperature (°C) |

PVC | 80–100 |

PET | 100–120 |

PP | 90–110 |

Once the film has been pre-heated, it is pulled over a mold to create the blister cavities. This is done using either vacuum or pressure, depending on the machine type and the product specifications. The vacuum process is typically used for shallow cavities, while pressure is more effective for deeper forms. It's important to monitor the cooling fans during this step to ensure the blisters retain their shape once formed. Any delay in cooling could lead to deformed blisters, compromising the packaging quality.

After the blisters are formed, the next step is feeding the product into the cavities. In automated production lines, bowl feeders, star wheels, or conveyors are used to place items directly into the blister cavities. For smaller or delicate products, such as medical devices, manual feeding is preferred to ensure precision and maintain sterility. It’s essential that the feeding speed is synchronized with the machine's cycle to prevent missing or overfilled blisters.

The final stage of the blister packaging process involves sealing the blister sheet and backing material under heat and pressure. This ensures the contents are securely enclosed. Depending on the product, additional steps such as nitrogen flushing may be required to reduce residual oxygen for extended shelf life, especially in pharmaceutical or food applications. After sealing, the sheet is cut into individual blister packs, with a focus on minimizing trim waste. Modern machines can achieve a trim waste of less than 2 mm, ensuring that the packaging process is both efficient and cost-effective.

Quality control is an essential part of the blister packaging process. Ensuring the blisters are defect-free and meet industry standards requires consistent inspection and data tracking throughout production. This section outlines the steps involved in in-line inspection and data logging to ensure high-quality output and full traceability.

One of the most effective ways to ensure product quality is through automated in-line inspection systems. Vision systems are often integrated into blister machines to check for defects during production. These systems scan each blister pack to detect issues such as missing products, broken blisters, or improper seals. If any defects are identified, the machine can automatically reject the faulty packs, ensuring only high-quality products proceed to the next stage.

The advantage of using vision systems is their ability to inspect each pack at high speeds, reducing the likelihood of human error and increasing production efficiency. Many modern systems are equipped with high-resolution cameras and advanced algorithms to detect even the smallest imperfections, ensuring that packaging meets the required standards.

Defect Type | Detection Method | Action Taken |

Missing Product | Vision system scanning | Reject defective blister packs |

Broken Blister | High-resolution cameras | Reject and isolate faulty packs |

Improper Seals | Vision system & pressure sensors | Reject and alert operator |

Alongside visual inspections, data logging is crucial for maintaining traceability and compliance with industry standards. During production, key parameters like temperature, pressure, and production quantity should be continuously recorded. These records can be stored in the machine's software and later exported to an Enterprise Resource Planning (ERP) system. This ensures all data is accurately logged for quality control purposes and regulatory compliance.

For pharmaceutical or food packaging, compliance with standards such as 21 CFR Part 11 is required. This regulation mandates that all production data be logged, including parameters like temperature and pressure, for traceability and audit purposes. Data logging also helps identify patterns that can improve future production runs, contributing to overall process optimization.

After the blister machine has completed its production cycle, it’s crucial to properly shut down and perform maintenance tasks to ensure the machine remains in optimal condition for future use. This section covers the key post-operation procedures, including machine cleaning, lubrication, and handling leftover materials.

Once the production is complete, turn off the machine and allow it to cool down before beginning any cleaning process. This is particularly important to prevent injury from hot components. Cleaning should be done with non-corrosive cleaners to avoid damaging the machine parts. Focus on cleaning molds, sealing platens, and feeding systems to remove any material residue or contamination. These components can accumulate dust, film, or material residues, which could interfere with future production runs if not properly cleaned.

For cleaning molds, use a soft cloth or brush to gently remove material build-up without causing scratches or damage. For more stubborn residues, use a cleaner that is specifically designed for blister machines and does not contain harsh chemicals that could damage sensitive parts.

Lubrication is key to maintaining smooth machine operation and extending its lifespan. Refer to the manufacturer’s guidelines for the recommended lubrication schedule and use the correct lubricants for moving parts. This includes gears, rollers, and servo drives, which can wear out faster without proper maintenance. Regular lubrication reduces friction and wear, ensuring that the machine operates efficiently and doesn’t suffer from unexpected breakdowns.

The lubrication schedule will vary depending on the model of the machine and its usage, but it is essential to perform this task regularly. For machines with heavy use, more frequent lubrication may be required. Be sure to clean any excess lubricant to prevent it from attracting dust and debris.

After production, handling leftover packaging materials properly is essential to prevent contamination and ensure they are stored safely for future use. Unused plastic films and backing materials should be stored in airtight containers. This prevents moisture from affecting the materials, especially if they are sensitive to environmental conditions. Proper storage ensures that materials maintain their quality and are ready for use when needed.

In addition to storing materials, it is important to document any production data from the shift. This includes recording the yield, any defects detected during the operation, and any adjustments made to machine settings. This information is crucial for quality control and helps in troubleshooting potential issues in future runs. Keep detailed production logs to maintain traceability and meet regulatory requirements.

Even with careful setup and operation, issues can arise during the blister packaging process. Understanding and addressing common problems quickly can minimize production delays and ensure the highest quality output. This section covers some of the most frequent issues encountered when working with blister machines and offers practical solutions.

One of the most common issues in blister packaging is cold seals. When the blister and backing material fail to bond properly, the seal may remain weak, leading to product leakage or contamination. Cold seals often occur when the sealing temperature or pressure is insufficient. To resolve this, increase the sealing temperature or pressure. Be sure to monitor the temperature closely, as too much heat can damage the material, while too little can result in weak seals.

If you notice consistent cold seals, it may also be helpful to check if the machine is operating at the optimal speed for the material being used. Adjusting the machine speed can sometimes correct minor sealing issues.

Blister deformation can occur when the cooling system is not working properly or if the forming speed is too high. When the blisters are not cooled rapidly enough, they can become misshapen or warped, compromising their structural integrity. To avoid deformation, check the cooling fans to ensure they are operational. If the fans are working properly, try lowering the forming speed. This will allow the material to cool properly before the blisters are removed from the mold, preventing warping or uneven shaping.

Deformation can also be caused by improperly set forming temperatures. Ensure the temperature is within the recommended range for the material being used to prevent thermal issues during the forming process.

Feeding jams are a common issue in blister machines and usually occur due to incorrect feeder speeds or clogged channels. These jams can disrupt the smooth flow of materials, leading to delays and defective products. If the feeder speed is too fast or too slow, the material may either jam or not align properly with the mold. To resolve this, adjust the feeder speed to match the machine’s cycle and the material’s characteristics.

If the problem persists, inspect the product channels for any blockages. Clean any material build-up or debris in the channels to prevent further jams. Regular cleaning and maintenance of the feeding system will help prevent this issue from becoming a recurring problem.

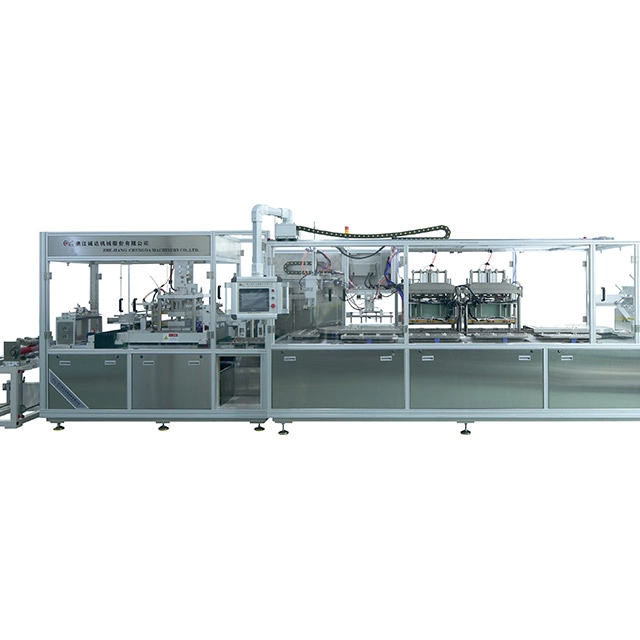

Operating a blister machine requires attention to detail at each stage. From preparation to shutdown, following proper procedures ensures high-quality production. Consistent maintenance, troubleshooting, and adherence to best practices help minimize waste and maximize efficiency. Chengda provides advanced equipment that supports these processes, offering reliable solutions for efficient, top-quality blister packaging.

A: A blister machine is a device used for packaging products in sealed plastic blisters. It forms cavities in plastic films, which are then sealed with backing materials.

A: The machine heats and forms plastic film over molds to create cavities. Products are then placed in these cavities and sealed with a backing material.

A: Proper calibration ensures consistent blister formation and sealing, preventing defects and maximizing production efficiency.